Drydocking of our Vessels

Our vessels being in great condition ensures the good service we can provide our clients. A very important factor for this is the maintenance and drydocking of our vessels from time to time since long-term exposure to seawater will damage parts of the ship if not taken care of, and in turn, interrupt services. As a part of providing our clients with non-compromising service, LSI makes sure our vessels are prepped and maintained with quality standards and as per Classification Society and Local regulations.

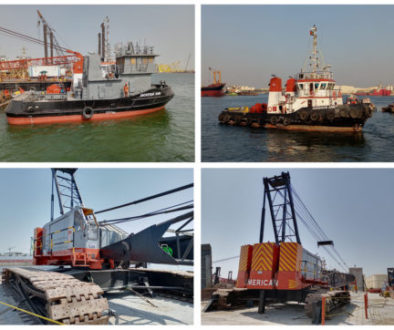

In the past few months, the below-mentioned vessels have undergone drydocking:

– Harbour Ann (Docking Period: 05-Oct-2020 – 15-Oct-2020)

– Mina Ann (Docking Period: 18-Oct-2020 – 16-Nov-2020)

– Suez Ann (Drydocking Period: 01-Nov-2020 – 09-Nov-2020)

– Manta Ann (Docking Period: Dec-2020)

– Tuna Ann (Docking Period: 16-Dec-2020 – 09-Jan-2021)

– Khor Ann 2 (Docking Period: 06-Jan-2021 – 25-Jan-2021)

– Stork Ann (Docking Period: Feb-2021)

– Kathleen Ann (Docking Period: Feb-2021 – Mar-2021)

Vessels: Tuna Ann, Harbour Ann, Kathleen Ann, Mina Ann, Stork Ann were drydocked in-house at LSI Jetty at Hamriyah Free Zone Port. While Khor Ann 2 and Suez Ann underwent drydocking at Al Jazeera Port.

The maintenance include Hull scraping and cleaning to remove sea growth, high-pressure wash with fresh water, steel repairs, Grinding and buffing full hull for painting, blasting, painting, Zinc anode replacements, renewal of tyre fenders, etc.

The Barges after Inspection of all barge tanks and damage markings undergo afloat steelwork on deck plating and side shell plating. Steelwork was carried out on deck and side shell plating as well.

Post repairs, surface preparation for full hull for painting, 4 coats of paint are done at the underwater area (Antifouling) and 2 coats above water level. For the deck of the barge, 2 coats are painted.

However, on Tugboats like Tuna Ann – which just returned back to base after the Hatta Dam Project, additional work will be done such as calibration of both tails shaft, rudders, propeller, and removing them out. Another important factor is to service all seawater line valves. Also, the gear-boxes and generators are serviced properly along with the overhauling of the main engines.

For the Jack-up Barge: Stork Ann, MPI thickness gauging is done for the spud (legs) and once completed with any maintenance, painting work is done as similar as tugboats or barges.

The final works are similar for all drydocking. NDT was carried out on welding joints and all zinc anodes renewed. After washing and painting the full hull, antifouling coats were applied on the side and bottom.

All vessels were successfully launched immediately after drydocking.

Well done to the Technical Department and all involved!